Question 1: where is the graphite rotor used?

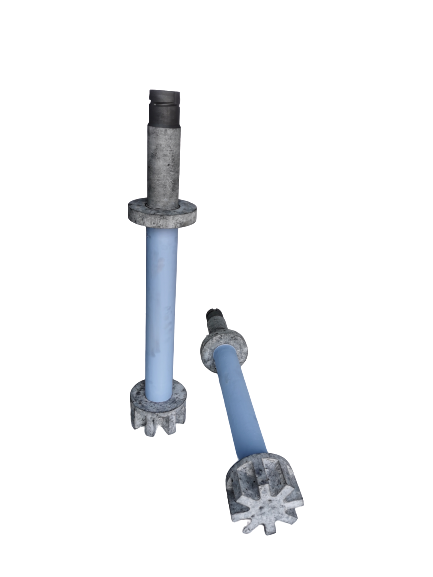

Graphite rotor is an accessory in aluminum alloy smelting equipment, mainly used in the purification process of aluminum alloy smelting. In the process of use, the transmission system drives the graphite rotor to rotate, and argon or nitrogen is blown into the melt through the rotating rod and nozzle. dispersed in the molten metal in the form of bubbles, and then continuously diffused through the rotation of the graphite rotor. After that, the impurity of the melt is absorbed by the bubble adsorption principle, so that the melt can be purified.

Question 2: what problems should be paid attention to in the use of graphite rotors?

- need to be preheated before use. Concrete operation: before soaking in molten aluminum, preheat about 100 mm above the liquid level for 5-10 minutes to avoid the influence of sudden cooling on the material. In addition, the gas must be injected before immersion in the solution. In order to avoid the blockage of the air hole on the nozzle, the rotor can put forward the liquid level before stopping the gas supply.

- Isolate the air. Nitrogen or argon is injected into the purifying box to isolate foreign air and prevent rotor oxidation. Caution: nitrogen or argon must be pure.

- The rotor is immersed in depth. The aluminum liquid surface of the reinforced sleeve is about 80 mm and 60 mm below the liquid level, which effectively increases the rotor oxidation resistance loss and scour.

- The transmission system is stable. If the relevant parts of the transmission equipment are loosened, it will affect the overall operation of the rotor and be easily damaged.

In addition to the use of precautions, in order to ensure the service life of graphite rotors, product quality is also very important.